Michigan (both the University of Michigan and the State of Michigan) has always been a leader in manufacturing innovations. The first modern manufacturing paradigm, Mass Production, was developed by Michigan’s Henry Ford in the 1910s. The first numerically controlled machine was developed in the 1940s by another Michigan inventor, Mr. John Parsons.

Michigan continued to show its manufacturing leadership from World War II’s “Arsenals of Democracy”, when Michigan produced military planes and tanks, to the 1970s Very Large Scale Integration (VLSI) revolution in Silicon Valley by Michigan Emerita Professor Lynn Conway. Professor Conway’s “Conway-Mead” design rules enabled VLSI and she is now recognized as the “the hidden hand behind Silicon Valley.”

In the present day, with NSF Engineering Research Centers on Reconfigurable Manufacturing Systems (under the leadership of Prof. Yoram Koren), and Wireless Integrated Manufacturing Systems (Prof Kensall Wise), and a state-of-the art facility for Nanofabrication, Michigan continues its tradition of leadership in advanced manufacturing.

Research

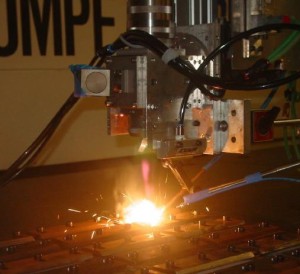

The University College of Engineering is the site of the Assembly and Manufacturing Systems Laboratory (AMSL), led by Professor S. Jack Hu. AMSL conducts research and innovation activities in manufacturing systems with the objectives of achieving efficiency (including quality, productivity and cost), responsiveness and sustainability. Dr. Hu also directs the Advanced Vehicle Manufacturing Collaborative Research Laboratory, which operates as an extension of General Motors to conduct critical research and development activities for GM that leverage UM faculty expertise. UM is also the home to several NSF industry/university cooperative research centers such as Dimensional Measurement and Control in Manufacturing, Intelligent Maintenance Systems, and Center for Lasers and Plasmas for Advanced Manufacturing.

Our faculty and students continue this excellence in manufacturing research, education and engagement with hundreds of industry partners through Integrated Manufacturing Systems Laboratories (IMSL) and the Lurie Nano Fabrication Facility (LNF) that brings together optics, solid-state electronics, materials, and nano-technology expertise to support fabrication, testing and measurement capability.

Most recently, the establishment of Lightweight Innovations for Tomorrow (LIFT; formerly the American Lightweight Materials Manufacturing Innovation Institute) has once again demonstrated the leadership position of the University of Michigan in manufacturing innovations.

Education

Manufacturing science and engineering have become very interdisciplinary. The field incorporates various engineering disciplines (e.g., mechanical engineering, electrical engineering, computer science and engineering, materials, chemical engineering, industrial and operation research, biomedical engineering, etc.) as well as non-engineering disciplines such as business, public policy, social science, natural resources and environment, etc. The College has established several interdisciplinary graduate programs.

The collaborations among the College of Engineering, Center for Entrepreneurship, the Ross School of Business, the College of Literature, Science and the Arts, the Ford School of Public Policy, and other units on the campus of the University of Michigan have propelled Michigan’s leadership in manufacturing research and education. The listing of College of Engineering graduate degrees offers several dual-degree/joint degree programs, as well as interdisciplinary graduate certificate programs.

Graduate degrees in Manufacturing are offered by the Integrative Systems and Design (IS+D) Department, including a joint degree with an MBA offered by ISD and the Ross School of Business. The Department of Mechanical Engineering offers a Bachelor of Science degree.

Entrepreneurship

Recent years have seen the University create an entrepreneurship ecosystem across campus, in which university units combine experience-based curricula, interdisciplinary project teams, faculty mentorship, student-led organizations, and campus programs and centers to help students and faculty embrace entrepreneurial innovation.

The College of Engineering is home to the Center for Entrepreneurship (CFE), which creates new academic programs, co-curricular activity, and programmatic support for students. CFE also provides innovation training to students and faculty. The University of Michigan was selected as one of the first three universities to offer the I-Corps program, along with Stanford University and Georgia Institute of Technology, as a grant from the National Science Foundation. CFE executes numerous successful I-Corps programs throughout the year, both at the University of Michigan and at universities and organizations across Michigan and the Midwest region.

Outreach

The Institute for Research on Labor, Employment, and the Economy (IRLEE) continues to engage with hundreds of large and small manufacturing firms (over 200 clients today) in the Midwest with technology adoption, identifying adjacent markets, and business incubation. IRLEE leads several national programs such as Defense Manufacturing Assistance Program, National Catalog of Excess Manufacturing Capacity, and the Technology and Commercialization Assistance Program, to name a few.

Policy

The College of Engineering recently established the Institute of Manufacturing Leadership—a “think-and-do” tank focusing on policy, education, and outreach—under the leadership of Professor Sridhar Kota, who made significant contributions to national policy in revitalizing American manufacturing.